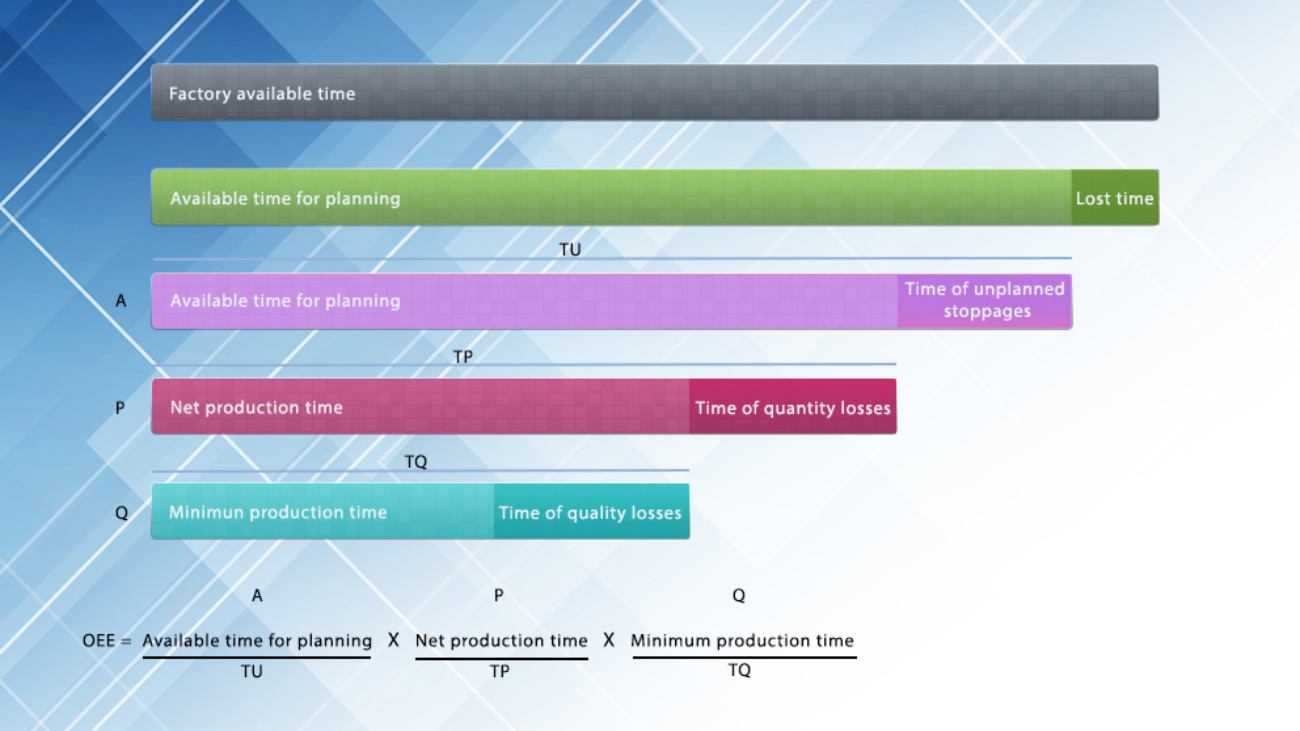

All time: the term ‘all time’ encompasses each and every minute of every day, constituting a span of 24 hours within a week.

Availability: Referring to the consideration of Availability Loss in the context of Overall Equipment Effectiveness (OEE). Availability Loss encompasses any events that cause the interruption of planned production for a significant duration. In an OEE program, the measurement of Availability Loss is typically carried out by recording the duration of both Unplanned Stops (unexpected interruptions) and Planned Stops (scheduled interruptions or downtime). By quantifying the time lost due to these stops, organizations can assess the impact on equipment availability and incorporate this information into the calculation of OEE .

Performance: Specifically focuses on the factors that result in Performance Loss during the manufacturing process. Performance Loss refers to any elements or issues that cause the process to operate at a speed lower than its maximum possible speed when it is running. In an OEE program, the measurement of OEE Performance is typically done by comparing the Actual Cycle Time (or Actual Run Rate) with the Ideal Cycle Time (or Ideal Run Rate). This comparison allows organizations to assess how efficiently the process is operating in terms of speed, identifying any deviations from the optimal performance level.

Cycle Time: Cycle Time denotes the real-time duration required to produce a single part. Within the context of Overall Equipment Effectiveness (OEE), this metric is computed by dividing the Run Time by the Total Count.

Run Rate: Run Rate represents the authentic pace of production during operational periods. In the framework of Overall Equipment Effectiveness (OEE), it is determined by dividing the Total Count by the Run Time.

Availability Loss: Availability Loss constitutes one of the OEE Losses. Availability factors in equipment failures, setup, end-up preparing to start working.

Breakdowns: Breakdowns are categorized as Unplanned Stops, resulting in time loss attributed to Machines Failure it could due to mechanical or electrical parts.

Breaks: Breaks designated as non-productive intervals during which the production process is intentionally halted, as the crew is scheduled to be away from the line. Launch and middle days meals are best examples. Some planners believe These downtime periods are typically omitted from OEE calculations some other planners don’t omit from OEE calculation they assume meal time is as heavy cost in factories and must be in planned stoppages.

Capacity: Capacity refers to the utmost production level achievable when equipment operates at maximum productivity . In other word speed of each machine per hours or minute on of exact definition of machine capacity. Manual operations can be defined as capacity categories.

Changeovers: Changeovers fall under the category of Planned Stoppages, it indicates that the manufacturing process is temporarily halted as part of a planned Setup, Make Ready, or Adjustment event, preventing production during this scheduled transition . Effect of changeover on OEE improvement is defined in SMED section.

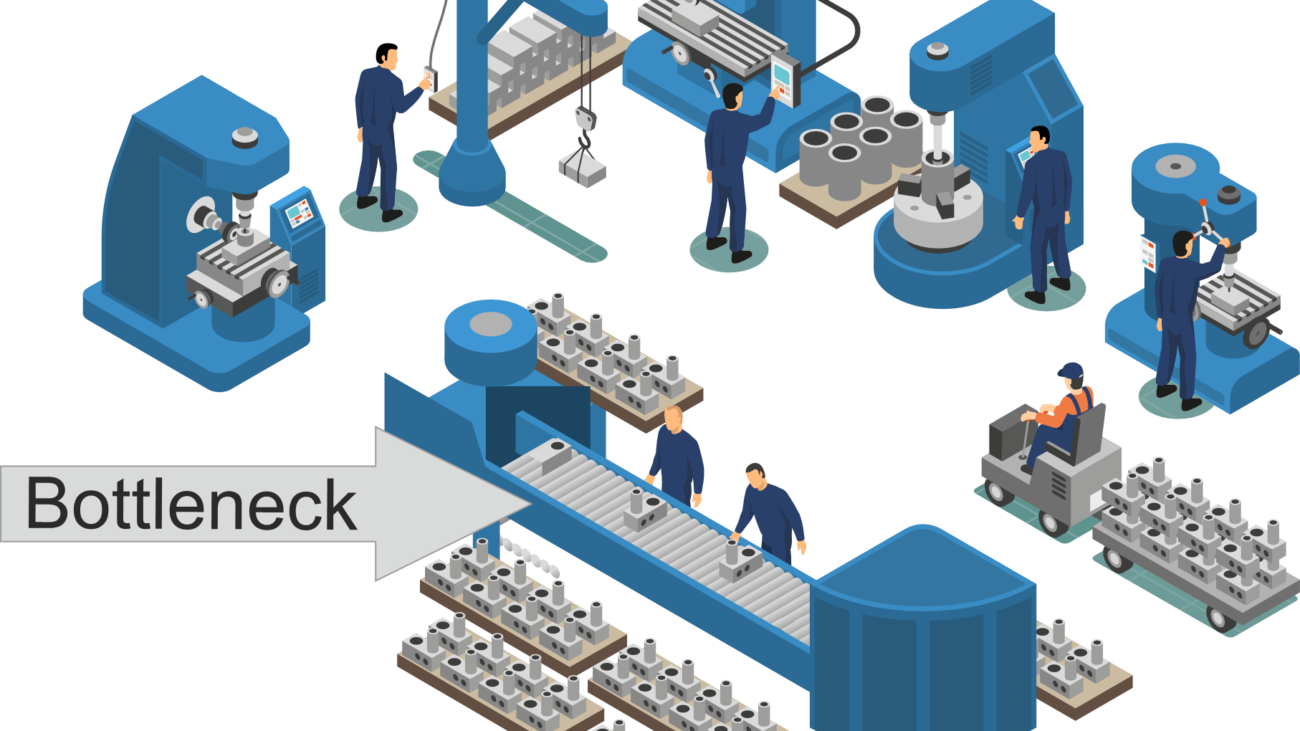

Theory of constraints (TOC): It is designed to help organizations identify and overcome constraints, or bottlenecks, in their processes in order to improve overall efficiency and achieve organizational goals.

Cycle Time: Cycle Time is the time to produce one part.

Defects: Defects are as a quality losses . Also defect is defined as any part that does not meet the required specifications upon initial production. Defective parts may undergo rework processes to meet standards, or they may be scrapped.

Downtime Loss: alternatively referred to as Stop Time, encompasses all periods when the manufacturing process was scheduled to be in operation but experienced interruptions due to Unplanned Stops. Downtime Loss represents the production time lost due to unforeseen shutdowns and stands as one of the three OEE Losses, directly impacting OEE Availability. It serves as a significant focal point for improvement initiatives .

Productive Time (OPT): Productive Time, denotes the effective operational duration once all losses have been deducted. An OEE score of 100% indicates that the process is operating at its maximum productivity.

Net Run Time: Net Run Time is the residual duration obtained by subtracting Schedule Loss, Availability Loss, and Performance Loss from the overall allotted time, known as All Time.

Planned Production Time: It refers to the overall duration during which equipment is anticipated to be in production. This is calculated by subtracting Schedule Loss from the total available time, known as All Time.

Planned Stoppages:

Planned Stoppages refer to scheduled interruptions in the manufacturing process. A Planned Stop occurs when the production line is intentionally halted due to a prearranged event, such as a changeover, setup, or make-ready process.

Speed Loss:

Sub optimal Speed occurs when the manufacturing process is in operation but is running at a slower pace than the Ideal Cycle Time. This type of loss is commonly referred to as Speed Loss.

Run Time: Run Time denotes the duration when the manufacturing process is slated for production and actively running. Calculated by deducting downtime from the planned production time, Run Time encompasses periods when the process may encounter small stops, reduced speed, and the production of reject parts.

SMED: It is a initiative aimed at minimizing setup time in manufacturing processes. The name is derived from the objective of reducing setup times to under ten minutes, typically represented by a single digit.

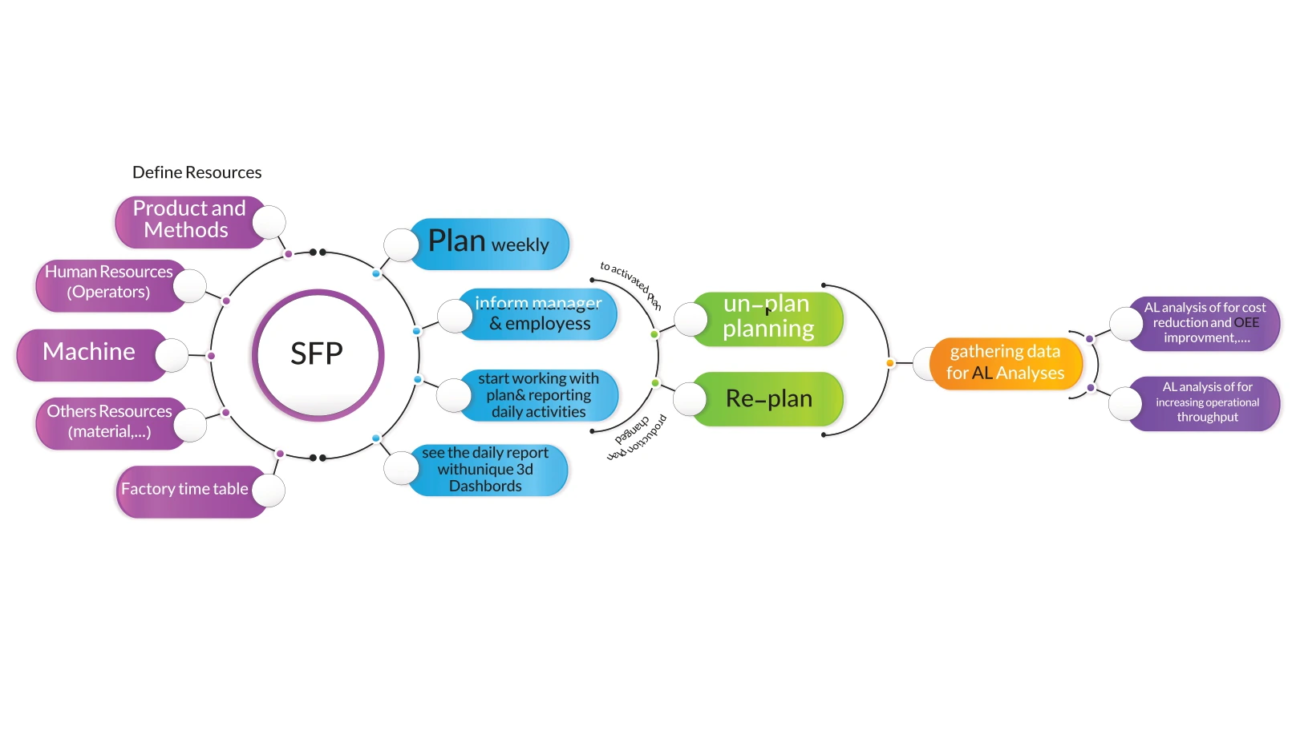

FOL: based on IOT, connecting factory equipment to Central smart app to monitor ongoing process in factory.