Think you want to cook your favorite dinner, when you are cooking, you understand that you’re missing one of the major ingredients. Annoying, right?

if it happens in the production process of your business, it will be more and more difficult. Running out of a specific raw material from your production line not only halts production, but can lead to back orders, sales loss, and a disrupt your supply chain workflows.

Material requirements planning (or MRPs) can prevent these types of issues. A lot of companies count on MRP software to keep – inventory management at optimal levels, minimize fixed Capital, optimize production planning, and finally simplify their supply chain management process.

What is Material Requirements Planning (MRP)?

Material Requirements Planning (MRP) is a business process strategy for integrating information that is incremental. MRPs are implemented from modular hardware and software programs linked to central databases that store and transmit business data and information.

Paper information systems and non-integrated computer systems that have paper outputs lead to many information errors such as missing data, redundant data, numerical errors that originate from their incorrect registration in the system, wrong calculations that originate from numerical errors, and Inappropriate decisions are caused by incorrect or outdated data. In addition, because in non-integrated systems, similar data are grouped differently in separate databases used in different functional areas, some data are unreliable. So, companies use MRP to determine raw and pack materials requirements for the manufacturing process integrally.

MRP systems support businesses to find out:

- Which raw/ pack materials it needs to be built.

- How much of those materials are required to produce the quantity of finished goods that will meet demand.

- When raw/ pack materials are needed.

With this knowledge, a business can set an optimize and efficient stock policy, and reach the supply chain up for success.

What is the history of MRP?

MRP evolved from the first commercial database management packages developed by Jane Thomas at IBM in the 1960s. The original structure was called BOMP (Board of Material Processor), which evolved in the next generation into a more general tool called DBOMP (Database Organization and Maintenance Program). These were implemented on mainframes such as the IBM/360.

The vision of MRP was to centralize and integrate business information in a way that would facilitate decision making for planning managers and increase overall – supply chain process effectiveness including Warehouse, Production line and also decrease a sales loss, fixed cost, in parallel improve the procurement process. In the 1980s, manufacturers developed systems to calculate resource requirements for a single Finished good (FG) run based on sales forecasts.

In order to calculate the raw materials needed to produce products and schedule the purchase of those materials along with the time required for equipment and labor, production managers realized that they would need computer and software technology to manage information.

Originally, for manufacturing operations, they built custom software programs that ran on mainframes.

Like ERP systems today, MRP was designed to give us a lot of information through a centralized database. However, the hardware, software, and relational database technology of the 1980s was not advanced enough to provide the speed and capacity needed to run these systems simultaneously, and the cost of these systems was too high for most commercial enterprises. However, the vision that was established, and changes in fundamental business processes along with successive advances in technology, have led to more cost-effective enterprise and application integration systems that large businesses and many small and medium-sized businesses use. They use them.

Why is material requirements planning important?

In order to produce products on-time, you’ll need to have the accurate amount of production inventory — but -calculating the volume of it is too difficult. If the volume of production is too much, the costs of your business increases unnecessarily, and if it is too little, you cannot meet customer demand because you confront a shortage of goods.

MRP systems make it easier to achieve this balance. MRP enables manufacturers to:

- Better plan inventory procurement.

- Always have sufficient stock on hand to create enough finished goods.

- Smooth Planning and overseeing the production process

- Simplify the overall supply chain

- Decrease inventory fixed capital / or increase working capital/ cash flow.

- Set the optimize Stock policy.

- Building optimum budget forecast.

What are the main features of an MRP system?

There are a few major features that every MRP system has to include.

1- MPS (Master production schedule) or sales forecast

MRP process starts with demand forecasting, and works backwards to determine how much FG stock is needed.

A good MRP system should support you build precise demand forecasts, so you can quickly calculate what required resource such as available time, Blue colors, you’ll need to manufacture them.

2- Data structure

MRPs store and reorganize your company’s unique production inventory data to make it easier for you to manage. The final result is clean, visible data that your business can use to simplify the manufacturing process.

3- Schedule planning

Timing procurement and scheduling production are very difficult, but an MRP system has to perform it easier. An appropriate MRP system let you know the best reorder point and time for each part of material , and can help you factor in lead times and current inventory levels to time replenishment perfectly.

MRP systems help you organize master production schedules (MPS), giving you an accurate view of labor, capacity , and activity requirements for every part of finished goods you manufacture.

4- Purchase planning

One of the most crucial functions of a material requirements planning system (or MRP) is helping you plan your procurement.

Your MRP system should provide you with a detailed list of materials (and accompanying amounts) that you need to maintain optimal inventory levels. You can then plan your purchases accordingly by considering other factors like production lead times and minimum order quantities.

5-Inventory management

Material requirements planning systems (or MRP) also help you keep track of all stocks/inventories you keep in the warehouses/ your organization. With software to monitor details such as varying shelf lives and inventory turnover, it is much easier for a business to manage their raw materials inventory over time and improve inventory management.

MRP process explained in 5 steps

Here are the five key steps that make up the material requirements planning process.

-

Step 1: Create your Product Tree (PT) and Bill of Materials (BOM)

The Product Tree is a fun, visual, and useful tool that gamifies product management. It helps product managers (PMs) organize, prioritize, and tame the barrage of product feature inputs from customers and internal stakeholders.

Before you can even get your MRP system up and running, you’ll need to create your company’s bill of materials (or BOM).

A bill of materials (or BOM) is just a hierarchical list of all the final products (or independent demand items) and the raw materials, components, and semi-finished goods needed to create them (or dependent demand items), as well as the quantities required.

The PT and BOM provides the data that an MRP needs to function. Thus, to get your MRP system to work, you’ll first need to input your BOM data correctly into your MRP.

From there, as long as your PT and BOM hierarchy is accurate, the MRP will take care of tracking material and component levels, identifying which products are dependent on other components or materials, and calculating what items in what quantities are needed by what date for the manufacturing process to go smoothly.

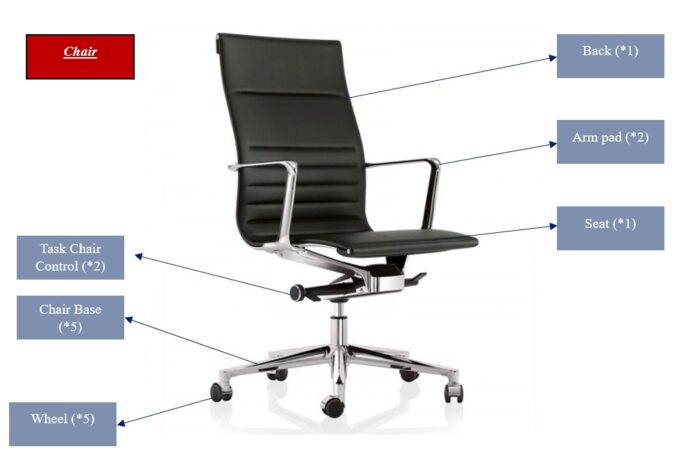

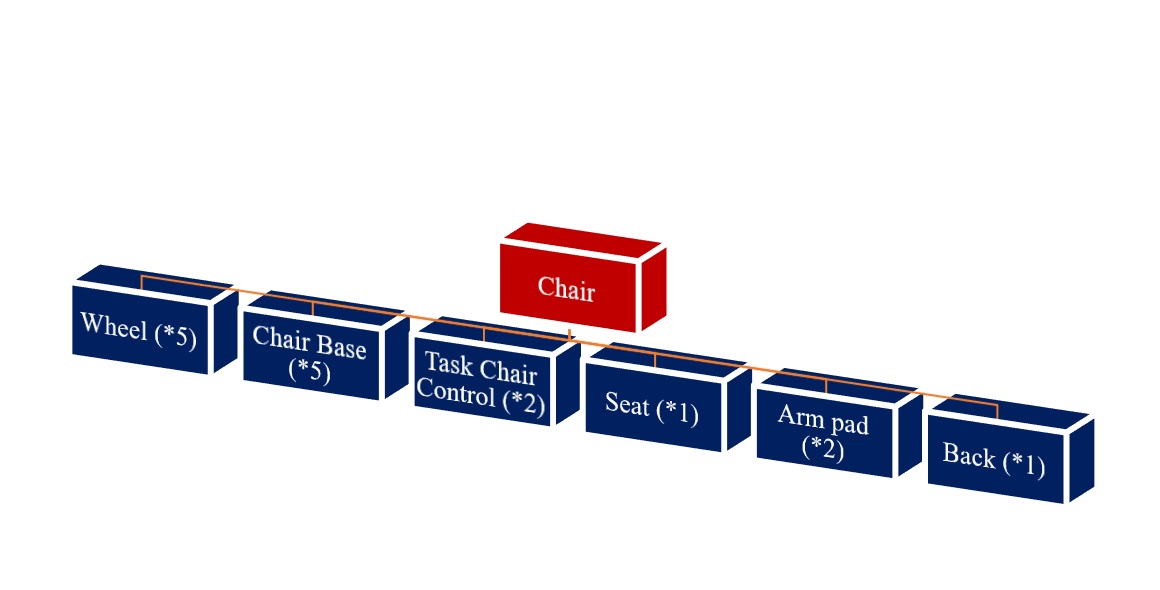

Examples of Product Tree:

Examples of BOM:

| BoM Name: | Chair | ||||||

| Producer Name: | … | ||||||

| NO | Level of PT

(Product Tree) |

Description | Current Inventory | Lead Time

(day) |

Consumption factor | Safety Stock | Ordering method |

| 1 | 0 | Chair | 10 | 7 | 1 | 0 | L4L |

| 2 | 1 | Wheel | 5 | 5 | 5 | 2 | POQ |

| 3 | 1 | Chair Base | 10 | 3 | 5 | 5 | PPB |

| 4 | 1 | Task Chair Control | 15 | 4 | 2 | 5 | LUC |

| 5 | 1 | Seat | 10 | 2 | 1 | 10 | 10 pieces |

| 6 | 1 | Arm Pad | 5 | 1 | 2 | 0 | LTC |

| 7 | 1 | Back | 5 | 2 | 1 | 0 | PPB |

Note: You must know that planning is from up to down and procurement is from down to up.

-

Step 2: Set goals and estimate demand

The MRP process works backwards from MPS This means it takes the amount of a product that you expect to sell in a given time period considering your stock policy, and breaks that number down to calculate how much of each raw material or component you’ll need to create that amount of FG.

For instance, imagine you must deliver 100 Chairs ( MPS) with above PT and BOM on the last day of a month ???(time period). = Yes, I mean it as time period

To Calculate the MPS, start by looking at your sales forecasts and customer orders.

-

Step 3: Check current inventory

In your MPS calculation, you should also factor in how many units of FGsyou already have. Tracking your inventory and checking demand against the inventory you currently have in stock prevents you from ending up with excess material that doesn’t get sold.

Your MRP system should give you visibility into inventory levels across multiple channels and locations, and help you identify which resources are available to use, which are already assigned to a manufacturing process, and how best to allocate production inventory overall.

For example, you need 100 Chairs on the last day of this month, and the chair’s consumption factor and current inventory are according to the above table. Please calculate the demand of Screw, Wheel and Truck?

| Description | Current Inventory | Consumption factor | Calculation |

| Chair | 10 | 1 | 100-10=90 |

| Wheel | 5 | 5 | (5*90) – 5 = 445 |

| Chair Base | 10 | 5 | (5*90) – 10 = 440 |

| Task Chair Control | 15 | 2 | (2*90) – 15 = 165 |

| Seat | 10 | 1 | (1*90) – 10 = 80 |

| Arm Pad | 5 | 2 | (2*90) – 5 = 175 |

| Back | 5 | 1 | (1*90) – 5 = 85 |

The demand of Wheel, Chair Base, Task Chair Control, Seat, Arm Pad and Back on the last day of this month are 445, 440, 165, 80, 175 and 85.

-

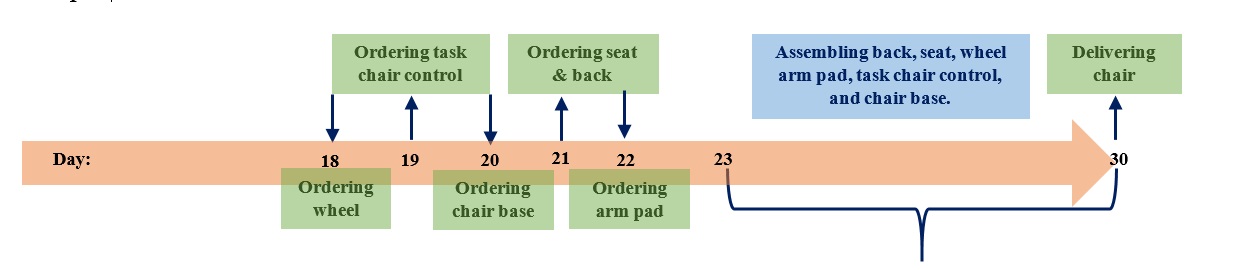

Step 4: Check lead time

Now you have to check lead time and determine the time that you should order the requirement of your product. For illustration the point, I want to calculate the day that we must order for above sample.

Note: Time that you must order the requirement of your product is the eighteenth day of the month.

-

Step 5: Determining the amount of batch order

There are six different ways to order a product or parts of a product. In this section, I want to describe these ways:

- Fixed batch

- L4L (lot 4 lot)

- LUC (labor unit cost)

- LTC (labor toral cost)

- PPB (part period balancing)

- POQ (production order quantity)

Fixed Batch:

If a seller says that “I just sell my products as a dozen (fixed batches)”, We have to order our requirements as fixed batches. Therefore, if we need 14 parts, we must order 2 dozen. It’s mean we will have 24 parts instead of 14 parts because of the condition of seller and we cannot do anything.

Example:

Question: Imagine the demand for a product is according to the below table. If the lead time is equal to 1 week, and the seller has said that his products will be sold in 8 pieces. Place orders using fixed batches as the approach for ordering.

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand | 0 | 6 | 12 | 21 | 19 | 5 | 14 | 23 | 7 | 40 |

| Receive | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? |

| Order | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? |

| Inventory | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? |

Answer with fixed batch:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand | 0 | 6 | 12 | 21 | 19 | 5 | 14 | 23 | 7 | 40 |

| Receive | 0 | 8 | 16 | 16 | 24 | 0 | 16 | 24 | 8 | 40 |

| Order | 8 | 16 | 16 | 24 | 0 | 16 | 24 | 8 | 40 | 0 |

| Inventory | 0 | 8-6=2 | 6 | 1 | 6 | 1 | 3 | 4 | 5 | 5 |

Calculation:

| Week | 1 | 2 | 3 | 4 | 5 |

| Demand | 0 | 6 | 12 | 21 | 19 |

| Receive | 0 | 8 | 16 | 16 | 24 |

| Order | 8 | 16 | 16 | 24 | … |

| Inventory | 0 | 8-6=2 | 18-12=6 | 22-21=3 | 25-19=6 |

Lot for lot (L4L):

In the method of ordering, the volume of the order is equal to the amount of our demand. As a example, we solve previous instance with L4L approach.

Answer with L4L:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand | 0 | 6 | 12 | 21 | 19 | 5 | 14 | 23 | 7 | 40 |

| Receive | 0 | 6 | 12 | 21 | 19 | 5 | 14 | 23 | 7 | 40 |

| Order | 6 | 12 | 21 | 19 | 5 | 14 | 23 | 7 | 40 | 0 |

| Inventory | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Note: In this way, as you can see in the above table, we do not have any inventory in our periods.

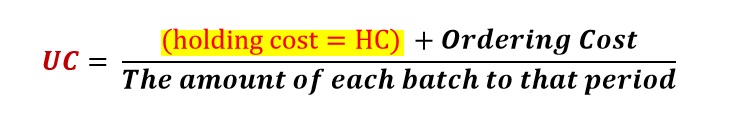

labor unit cost (LUC):

In the way of ordering, we use the minimum of cost per each unit, and we have to do these items step by step:

- We start with the first period and calculate the total cost of maintenance and ordering for each batch to that period.

- The output of the first step is divided into total ordered products for counting the cost for each product.

- Until UC decreases, we continue our calculation. When UC is broken and starts to increase, we stop our calculation.

- Batch order is equal to the minimum of

- We repeat our steps according to above guideline until meet our demand.

Question: Imagine the demand for a product is according to the below table. If the lead time is equal to 2 weeks, and holding cost is 0.05 $ per week per product and the cost of ordering is 5.75 $. Place orders using LUC as the approach for ordering.

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Demand | 12 | 15 | 9 | 17 | 8 | 10 | 16 | 7 | 11 |

| Receive | ? | ? | ? | ? | ? | ? | ? | ? | ? |

| Order | ? | ? | ? | ? | ? | ? | ? | ? | ? |

| Inventory | ? | ? | ? | ? | ? | ? | ? | ? | ? |

Answer with LUC:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Demand | 12 | 15 | 9 | 17 | 8 | 10 | 16 | 7 | 11 |

| Previous receive | 53 | ||||||||

| Receive | 52 | ||||||||

| Order | 52 | ||||||||

| Inventory | 53-12=41 | 41-15=26 | 26-9=17 | 17-17=0 | 52-8=44 | 44-10=34 | 34-16=18 | 18-7=11 | 11-11=0 |

Calculation:

| Period | Order’s amount | (1) | Ordering cost (2) | Total cost (1+2) | UC |

| 1 | 12 | 0 | 5.75 | 5.75 | |

| 1,2 | 12+15= 27 | 15 Product * 1 Week * 0.05 $ = 0.75 | 5.75 | 6.5 | |

| 1,2,3 | 27+9= 36 | (15*1*0.05) + (9*2*0.05) = 1.65 | 5.75 | 7.4 | |

| 1,2,3,4 | 36+17= 53 | (15*1*0.05) + (9*2*0.05) + (17*3*0.05) = 4.2 | 5.75 | 9.95 | |

| 1,2,3,4,5 | 53+8= 61 | (15*1*0.05) + (9*2*0.05) + (17*3*0.05) + (8*4*0.05) = 5.8 | 5.75 | 11.55 | |

| 5 | 8 | 0 | 5.75 | 5.75 | |

| 5,6 | 8+10= 18 | (10*1*0.05) = 0.5 | 5.75 | 6.25 | |

| 5,6,7 | 18+16= 34 | (10*1*0.05) + (16*2*0.05) = 2.1 | 5.75 | 7.85 | |

| 5,6,7,8 | 34+7= 41 | (10*1*0.05) + (16*2*0.05) + (7*3*0.05) = 3.15 | 5.75 | 8.9 | |

| 5,6,7,8,9 | 41+11= 52 | (10*1*0.05) + (16*2*0.05) + (7*3*0.05) + (11*4*0.05) = 5.35 | 5.75 | 11.1 |

Labor toral cost (LTC):

In this method the cost of ??? (holding cost=HC) is calculated cumulative as long as this calculation is equal or close to ordering cost, we can stop and determine batch order. We want to solve previous sample with this way.

Answer with LTC:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Demand | 12 | 15 | 9 | 17 | 8 | 10 | 16 | 7 | 11 |

| Previous receive | 61 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Receive | 0 | 0 | 0 | 0 | 0 | 44 | 0 | 0 | 0 |

| Order | 0 | 0 | 0 | 44 | 0 | 0 | 0 | 0 | 0 |

| Inventory | 61-12= 49 | 49-15= 34 | 34-9= 25 | 25-17= 8 | 8-8= 0 | 44-10= 34 | 34-16= 18 | 18-7=11 | 11-11= 0 |

| Period | Order’s amount | Ordering cost | |

| 1 | 12 | 0 | 5.75 |

| 1,2 | 12+15= 27 | 15 Product * 1 Week * 0.05 $ = 0.75 | 5.75 |

| 1,2,3 | 27+9= 36 | (15*1*0.05) + (9*2*0.05) = 1.65 | 5.75 |

| 1,2,3,4 | 36+17= 53 | (15*1*0.05) + (9*2*0.05) + (17*3*0.05) = 4.2 | 5.75 |

| 1,2,3,4,5 | 53+8= 61 | (15*1*0.05) + (9*2*0.05) + (17*3*0.05) + (8*4*0.05) = 5.8 | 5.75 |

| 6 | 10 | 0 | 5.75 |

| 6,7 | 10+16= 26 | (16*1*0.05) = 0.8 | 5.75 |

| 6,7,8 | 26+7= 33 | 0.8 + (7*2*0.05) = 1.5 | 5.75 |

| 6,7,8,9 | 33+11= 44 | 1.5 + (11*3*0.05) = 3.15 | 5.75 |

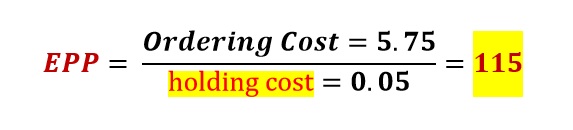

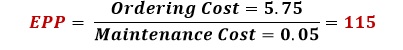

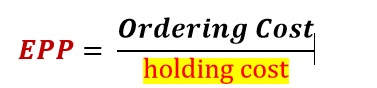

Part period balancing (PPB):

In the way of ordering, we have to do these steps:

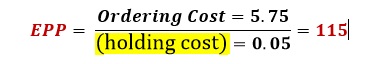

- First of all, calculate EPP:

- In each period we have to multiply the demand of the period by the number of period which product must be kept.

- Cumulatively calculate the value of previous part to approach to EPP.

- When the value of item 2 approaches to item 3, you must stop this work and determine batch order.

Now, we can solve previous example with PPB way.

Answer with PPB:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Demand | 12 | 15 | 9 | 17 | 8 | 10 | 16 | 7 | 11 |

| Previous receive | 61 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Receive | 0 | 0 | 0 | 0 | 0 | 44 | 0 | 0 | 0 |

| Order | 0 | 0 | 0 | 44 | 0 | 0 | 0 | 0 | 0 |

| Inventory | 61-12= 49 | 49-15= 34 | 34-9= 25 | 25-17= 8 | 8-8= 0 | 44-10= 34 | 34-16= 18 | 18-7=11 | 11-11= 0 |

| Period | Order’s amount | Last demand (1) | Number of periods that maintain products (2) | (1)*(2)Cumulative |

| 1 | 12 | 12 | 0 | 0 |

| 1,2 | 12+15= 27 | 15 | 1 | 15 |

| 1,2,3 | 27+9= 36 | 9 | 2 | 15+18= 33 |

| 1,2,3,4 | 36+17= 53 | 17 | 3 | 33+48= 84 |

| 1,2,3,4,5 | 53+8= 61 | 8 | 4 | 84+32= 116 |

| 6 | 10 | 10 | 0 | 0 |

| 6,7 | 10+16= 26 | 16 | 1 | 16 |

| 6,7,8 | 26+7= 33 | 7 | 2 | 16+14= 30 |

| 6,7,8,9 | 33+11= 44 | 11 | 3 | 30+33= 63 |

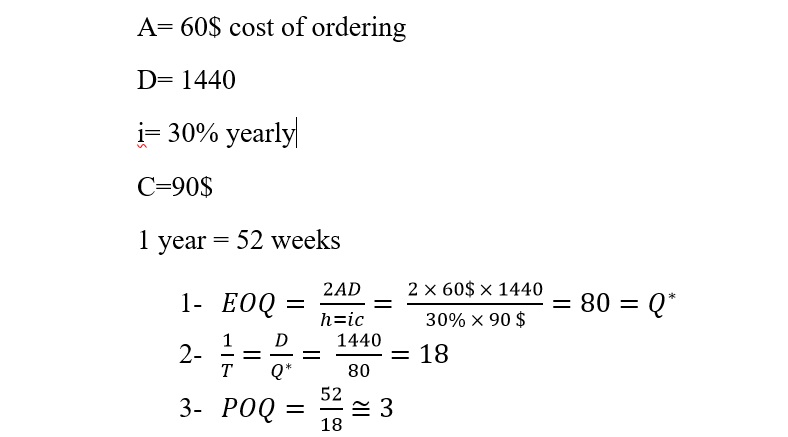

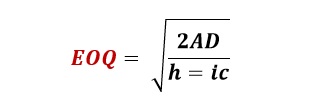

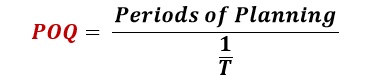

Production order quantity (POQ):

-

- Calculate EOQ (economic order quantity)

- Calculate

- Calculate POQ

- Order based on the value of POQ.

- Calculate EOQ (economic order quantity)

Question: Imagine the demand for a product is according to the below table in 1 year. If the lead time is equal to 2 weeks, the yearly demand is 1440, the cost of ordering is 60$, (holding cost) is 30% yearly, the cost of product is 90$ and periods of planning is 52 weeks. Place orders using POQ as the approach for ordering.

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Demand | 0 | 0 | 20 | 34 | 8 | 50 | 0 | 51 | 0 | 9 | 38 | 13 |

| Previous receive | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? |

| Receive | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? |

| Order | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? |

| Inventory | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? | ? |

Answer with POQ:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |||

| Demand | 0 | 0 | 20 | 34 | 8 | 50 | 0 | 51 | 0 | 9 | 38 | 13 | |||

| Receive | 0 | 0 | 62 |

0 |

0 | 101 |

0 |

0 | 0 | 60 |

0 |

0 | |||

| Order | 62 | 0 | 0 | 101 | 0 | 0 | 0 | 60 | 0 | 0 | 0 | 0 | |||

| Inventory | 0 | 0 | 42 | 8 | 0 | 51 | 51 | 0 | 0 | 51 | 13 | 0 |

Note: In every approach which has the (holding cost), the unit of this scale has to be according to the unit of period. For instance, in all our examples, we calculate based on week.

Right now, I want to conclude bullet 5 with a sensible example that include all topics which has to be followed by employees.

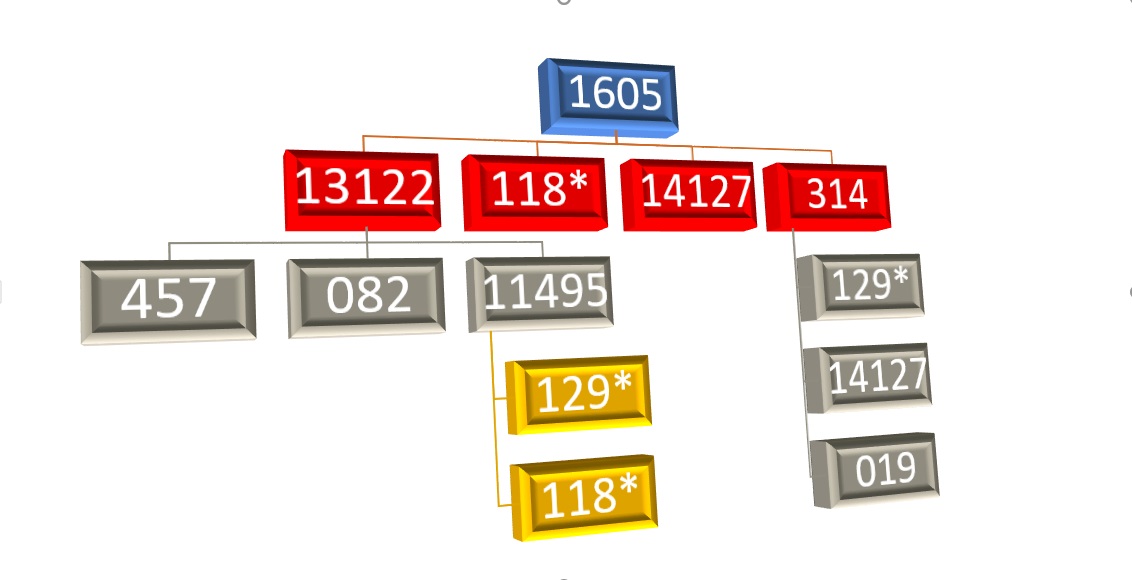

Question: Imagine a product with the below tree and demand according to the below table.

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand 1605 | 0 | 20 | 0 | 10 | 10 | 20 | 5 | 0 | 35 | 10 |

| Level | Technical Number | Consumption Factor | Order Method | Lead Time | Safety Stock | Current Inventory |

| 0 | 1605 | 1 | L4L | 1 W | 0 | 0 |

| 1 | 13122 | 2 | 15 Pieces | 2W | 0 | 0 |

| 2 | 457 | 3 | 40 Pieces | 2W | 10 | 0 |

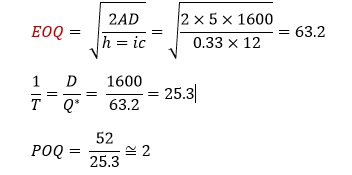

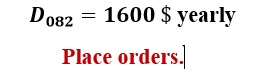

| 2 | 082 | 2 | POQ | 2W | 0 | 20 |

| 2 | 11495 | 2 | PPB | 2W | 0 | 0 |

| 3 | 129 | 3 | L4L | 3W | 40 | 20 |

| 1 | 118 | 2 | 100 Pieces | 2W | 0 | 40 |

| 1 | 314 | 2 | PPB | 2W | 20 | 0 |

| 1 | 14127 | 5 | 100 Pieces | 2W | 0 | 0 |

| 3 | 019 | 2 | 40 Pieces | 1W | 20 | 0 |

Ordering cost: 5.75 $ (Except 082) – Ordering cost: 5 $ for 082

(holding cost): 0.05 $ per week (Except 082) – (holding cost): 0.33 per month for 082

Answers:

| Week/1605 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand | 0 | 20 | 0 | 10 | 10 | 20 | 5 | 0 | 35 | 10 |

| Receive | 0 | 20 | 0 | 10 | 10 | 20 | 5 | 0 | 35 | 10 |

| Order | 20 | 0 | 10 | 10 | 20 | 5 | 0 | 35 | 10 | 0 |

| Inventory | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Week/13122 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand | 40 | 0 | 20 | 20 | 40 | 10 | 0 | 70 | 20 | 0 |

| Previous receive | 45 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Receive | 0 | 0 | 15 | 30 | 30 | 15 | 0 | 75 | 15 | 0 |

| Order | 15 | 30 | 30 | 15 | 0 | 75 | 15 | 0 | 0 | 0 |

| Inventory | 5 | 5 | 0 | 10 | 0 | 5 | 5 | 10 | 5 | 5 |

| Week/457 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand | 45 | 90 | 90 | 45 | 0 | 225 | 45 | 0 | 0 | 0 |

| Previous receive | 80 | 80 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Receive | 0 | 0 | 80 | 40 | 0 | 240 | 40 | 0 | 0 | 0 |

| Order | 80 | 40 | 0 | 240 | 40 | 0 | 0 | 0 | 0 | 0 |

| Inventory | 35 | 25 | 15 | 10 | 10 | 25 | 20 | 20 | 20 | 20 |

Note: Safety Stock means that the inventory has to be equal to safety stock in the minimum gesture. For instance, the minimum inventory must be 10 instead of 0 in 457.

| Week/082 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Demand | 30 |

60 |

60 |

30 | 0 | 150 | 30 | 0 | 0 | 0 | ||

| Previous receive | 70 | 0 | 0 | 0 | 0 |

0 |

0 | 0 | 0 | 0 | ||

| Receive | 0 | 0 | 90 | 0 | 0 | 180 | 0 | 0 | 0 | 0 | ||

| Order | 90 | 0 | 0 | 180 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| Inventory

Initial =20 |

60 | 0 | 30 | 0 | 0 | 30 | 0 | 0 | 0 | 0 |

Note: If we have initial inventory, we must consider it into our order. For example, we must order 70 instead of 90 in 082, because initial inventory is equal to 90

| Week/11495 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand | 30 | 60 | 60 | 30 | 0 | 150 | 30 | 0 | 0 | 0 |

| Previous receive | 90 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Receive | 0 | 0 | 90 | 0 | 0 | 180 | 0 | 0 | 0 | 0 |

| Order | 90 | 0 | 0 | 180 | 0 | 0 | 0 | 0 | 0 | 0 |

| Inventory | 60 | 0 | 30 | 0 | 0 | 30 | 0 | 0 | 0 | 0 |

| Period | Order’s amount | Last demand (1) | Number of periods that maintain products (2) | (1)*(2)Cumulative |

| 1 | 30 | 30 | 0 | 0 |

| 1,2 | 90 | 60 | 1 | 60 |

| 1,2,3 | 150 | 60 | 2 | 180 |

| 3 | 60 | 60 | 0 | 0 |

| 3,4 | 90 | 30 | 1 | 30 |

| 3,4,5 | 90 | 0 | 2 | 30 |

| 3,4,5,6 | 240 | 150 | 3 | 480 |

| 6 | 150 | 150 | 0 | 0 |

| 6,7 | 180 | 30 | 1 | 30 |

Note: Repetitive product: 129 and 118; Question: which we can plan for production? why?

Answer: Certainly 118, because we could plan each product that is above 118 but we have not calculated orders for 315 which is above 129 yet, so it’s clear we cannot order 129 as long as doing plan for 315.

| Week/118 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand/ 1605 | 40 | 0 | 20 | 20 | 40 | 10 | 0 | 70 | 20 | 0 |

| Demand/ 11495 | 180 | 0 | 0 | 360 | 0 | 0 | 0 | 0 | 0 | 0 |

| Total Demand | 40+180=220 | 0 | 20+0=0 | 20+360=380 | 40+0=40 | 10+0=10 | 0 | 70+0=70 | 20 | 0 |

| Previous receive | 200 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Receive | 0 | 0 | 0 | 400 | 100 | 0 | 0 | 0 | 100 | 0 |

| Order | 0 | 400 | 100 | 0 | 0 | 0 | 100 | 0 | 0 | 0 |

| Inventory

Initial=40 |

240-220=20 | 20 | 20-20=0 | 400-380=20 | 20+100-40=80 | 70 | 70 | 70-70=0 | 100-20=80 | 80 |

| Week/314 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand | 40 | 0 | 20 | 20 | 40 | 10 | 0 | 70 | 20 | 0 |

| Previous receive | 80+20=100 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Receive | 0 | 0 | 0 | 0 | 120 | 0 | 0 | 0 | 20 | 0 |

| Order | 0 | 0 | 120 | 0 | 0 | 0 | 20 | 0 | 0 | 0 |

| Inventory

SS=20 |

100-40= 60 | 60 | 60-20= 40 | 40-20=20 | 20+120-40=100 | 100-10=90 | 90 | 90-70=20 | 20+20-20=20 | 20 |

| Period | Order’s amount | Last demand (1) | Number of periods that maintain products (2) | (1)*(2)Cumulative |

| 1 | 40 | 40 | 0 | 0 |

| 1,2 | 40 | 0 | 1 | 0 |

| 1,2,3 | 40+20=60 | 20 | 2 | 20*2=40 |

| 1,2,3,4 | 60+20=80 | 20 | 3 | 40 + (20*3) = 100 |

| 1,2,3,4,5 | 80+40=120 | 40 | 4 | 100 + (4*40) = 260 |

| 5 | 40 | 40 | 0 | 0 |

| 5,6 | 40+10=50 | 10 | 1 | 1*10 = 10 |

| 5,6,7 | 50 | 0 | 2 | 10 |

| 5,6,7,8 | 50+70=120 | 70 | 3 | 10+ (3*70) = 220 |

| 5,6,7,8,9 | 120+20=140 | 20 | 4 | 220+(4*80) = 300 |

| 9 | 20 | 20 | 0 | 0 |

| 9,10 | 20+0=20 | 0 | 1 | 0 |

| Week/129 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Demand/ 314 | 0 | 0 | 3*120=360 | 0 | 0 | 0 | 3*20=60 | 0 | 0 | 0 |

| Demand/ 11495 | 270 | 0 | 0 | 540 | 0 | 0 | 0 | 0 | 0 | 0 |

| Total Demand | 270 | 0 | 360 | 540 | 0 | 0 | 60 | 0 | 0 | 0 |

| Previous receive | 290 | 0 | 360 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Receive | 0 | 0 | 0 | 540 | 0 | 0 | 60 | 0 | 0 | 0 |

| Order | 540 | 0 | 0 | 60 | 0 | 0 | 0 | 0 | 0 | 0 |

| Inventory

Initial=20 SS=40 |

290+20-270= 40 | 40 | 360+40-360= 40 | 540+40-540= 40 | 40 | 40 | 40 | 40 | 40 | 40 |

Is an MRP system essential?

it’s worthy weighing carefully advantages and disadvantages to better assess the value of an MRP system.

Advantages with an MRP system

An MRP system ensures that you have all the essential raw materials for production, which yield the subsequent benefits:

- enhanced efficiency in the manufacturing system.

- Decreased risk of errors as a result of automating manual tasks.

- Reducing supplying lead times

- Increasing customer satisfaction.

- Optimized inventory levels

- Decreasing stockouts

Disadvantages with an MRP system

There are a fewrisks :

- Input data must be precise to present appropriate result

- MRPs can be sophisticated and expensive to develop

MRP vs ERP explained

While both material requirements planning (MRP) and enterprise resource planning (ERP) play a critical role in helping you plan your resources, their scopes are different.

ERP systems plan and manage resources for multiple organizational functions, including finance, accounting, payroll, sales, operations, manufacturing, supply chain, suppliers management, and much more. Businesses use ERP systems to maintain resource visibility across departments, and to simplify the resource management process for the whole company.

MRP systems, on the other hand, focus particularly on production resource planning — that is, planning and managing the resources involved in the manufacturing process. MRP systems are mostly used by manufacturing companies.

Material requirements planning FAQs

Here are answers to some of the top questions about material requirements planning.

- What is the importance of material requirement planning?

MRP is a major section of building a simplified, efficient manufacturing process. MRP systems help you make sure you have all the raw materials and essential parts for manufacturing products.

Also, MRPs allows a producer to keep its production schedule, simplify its production process, decrease customer lead times, and improve customer satisfaction.

- What are the types of MRP?

MRP is just one type of resource planning system.

- What comes after MRP is completed?

After MRP is completed, a business must control the production process, receive raw materials at their warehouse, and store thestock.