Efficiency reigns supreme in manufacturing, where every step, every adjustment, and every motion is meticulously orchestrated to yield maximum output with minimal input. At the heart of this pursuit lies the art of process optimization – a strategic endeavor that harmonizes human efforts, machine capabilities, and data-driven insights to streamline operations and propel productivity to unprecedented heights.

Plan Optimization is a critical process that involves analyzing and refining production schedules, resource allocations, and other key factors to ensure that your manufacturing operations are running at their full potential. In today’s highly competitive and rapidly evolving manufacturing landscape, the ability to effectively optimize your production plans is a critical competitive advantage. In the realm of modern industry, the optimization of the manufacturing process emerges as a pivotal factor in enhancing efficiency, reducing costs, and maintaining competitive advantage.

This article delves into the intricacies of Plan Optimization in the manufacturing sector, starting with an overview of the concept and its key elements. It further explores various approaches to plan optimization, highlighting the tools and technologies that play a crucial role in achieving operational excellence. Through case studies, readers will gain insights into real-world applications and successes of plan optimization strategies.

The article also addresses common challenges organizations face in optimizing their production processes and outlines the tangible benefits of effective plan optimization. Finally, it looks ahead to future trends in the field, providing a comprehensive guide for professionals aiming to harness the power of plan optimization to drive their manufacturing processes forward.

Whether you’re a seasoned manufacturing veteran or just starting out, this article will provide you with the insights and practical advice you need to unlock the potential of plan optimization in your business.

What is Plan Optimization?

Plan Optimization in the manufacturing process involves a systematic approach aimed at enhancing efficiency and productivity. This concept encompasses various methodologies and technologies designed to refine every aspect of production. Key techniques include product design optimization, which focuses on the shape, size, and functionality of products to meet market demands effectively. Moreover, plan optimization incorporates advanced strategies such as Planning Optimization for master planning, which significantly reduces the time required for material requirements planning (MRP), allowing for more frequent and efficient planning cycles.

The Nexus of Process Optimization and Efficiency

In the manufacturing arena, the pursuit of efficiency is a relentless quest, fueled by the desire to extract maximum value from every resource at hand. Process optimization emerges as a critical enabler, meticulously fine-tuning the intricate dance between human operators, sophisticated machinery, and the myriad tasks that culminate in the creation of finished goods.

Contrary to the notion of merely churning out products en masse, true efficiency lies in the harmonious interplay of various elements – from the precise orchestration of checks and adjustments to the seamless flow of materials and information. By optimizing these processes, manufacturers can unlock a realm where every input is strategically leveraged, every motion is purposeful, and every output is a testament to the synergy between human ingenuity and technological prowess.

Understanding the Importance of Plan Optimization

In the fast-paced and highly competitive manufacturing world, the ability to quickly adapt to changing market conditions and customer demands is essential. Plan Optimization plays a crucial role in this process by enabling you to:

- Improve resource utilization: By optimizing your production plans, you can ensure that your equipment, labor, and other resources are being used as efficiently as possible, reducing waste and maximizing output.

- Enhance production flexibility: Optimized plans allow you to respond more quickly to changes in demand, enabling you to adjust your production schedules and allocate resources accordingly.

- Reduce inventory and storage costs: Improved planning can help you minimize the amount of work-in-progress and finished goods inventory, reducing the costs associated with storage and handling.

- Boost profitability: The cumulative effects of improved resource utilization, production flexibility, and cost savings can result in a significant boost to your bottom line, making plan optimization a critical competitive advantage.

The Difference between Process and Production Optimization

Process optimization and production optimization are two key concepts in the field of operations management that focus on improving efficiency, reducing costs, and maximizing output in a business or manufacturing setting. While both concepts aim to enhance overall performance, they have distinct approaches and objectives.

While process optimization and production optimization share the common goal of improving performance and efficiency in a business or manufacturing setting, they differ in scope, objectives, and approach. Understanding the distinctions between these two concepts can help organizations implement targeted strategies to optimize their operations effectively. Here is a detailed explanation of the key differences between process and production optimization:

Production Optimization:

- Production optimization focuses on improving the overall output, capacity, and performance of a production system or manufacturing facility.

- The primary objective of production optimization is to maximize output, minimize downtime, reduce costs, and improve the overall efficiency of the production process.

- Production optimization typically involves optimizing equipment utilization, minimizing setup times, improving scheduling and planning, and enhancing resource allocation to maximize production capacity.

- Examples of production optimization include implementing predictive maintenance strategies, optimizing production schedules, adopting advanced manufacturing technologies, and using data analytics to improve decision-making.

Key Differences:

- Scope: Process optimization focuses on improving individual processes or workflows within an organization, while production optimization looks at optimizing the overall production system or manufacturing operations.

- Objectives: Process optimization aims to enhance efficiency, quality, and productivity at each stage of a process, while production optimization focuses on maximizing output, minimizing costs, and improving overall production performance.

- Approach: Process optimization involves analyzing and improving specific processes through reengineering and redesign, while production optimization focuses on optimizing production systems, equipment, and resources to maximize output and efficiency.

Decoding the Distinction: Process vs. Production Optimization

While the terms “process optimization” and “production optimization” are often used interchangeably, they represent distinct yet complementary facets of the manufacturing equation. Process optimization zeroes in on the intricate steps within a specific production stage, meticulously refining and streamlining each phase to maximize efficiency and minimize waste.

On the other hand, production optimization takes a holistic view, encompassing the entire manufacturing ecosystem – from equipment layout and inventory protocols to material flow and facility design. By harnessing real-time data, advanced analytics, and sophisticated modeling techniques, production optimization aims to enhance the overall system performance, ensuring that resources are optimally allocated and bottlenecks are proactively identified and mitigated.

Key Factors to Consider for Successful Plan Optimization

Achieving successful Plan Optimization in manufacturing requires a comprehensive understanding of the various factors that can impact your production operations.

Some of the key factors to consider include:

- Production Capacity: Accurately assessing your production capacity, including the capabilities of your equipment, labor, and other resources, is essential for developing effective production plans.

- Demand Forecasting: Accurate demand forecasting is crucial for ensuring that your production plans are aligned with customer needs and market trends.

- Process Complexity: Analyzing the complexity of your manufacturing processes, including the interdependencies between different production stages, can reveal opportunities for optimization.

- Data Availability and Quality: Ensuring that you have access to accurate, up-to-date data on your production operations is critical for effective plan optimization.

- Organizational Alignment: Securing buy-in and cooperation from across your organization, from the shop floor to the executive suite, is essential for successful plan optimization implementation.

Strategy development in plan optimization focuses on defining clear objectives that need to be maximized or minimized within the manufacturing process.

Approaches to Plan Optimization

Lean Manufacturing

Lean Manufacturing focuses on maximizing customer value while minimizing waste. This approach identifies and eliminates non-value-added activities, enhancing efficiency and quality. Key principles include Value Stream Mapping, which analyzes the flow of materials and information to pinpoint waste, and Just-in-Time production, which reduces inventory costs by producing only what is needed when it is needed.

Six Sigma

Six Sigma aims to improve manufacturing quality by reducing defects and variability in processes. The methodology is highly data-driven, utilizing statistical tools to identify and eliminate errors. The DMAIC framework—Define, Measure, Analyze, Improve, and Control—is central to Six Sigma, providing a structured approach to problem-solving that ensures sustainable quality improvements.

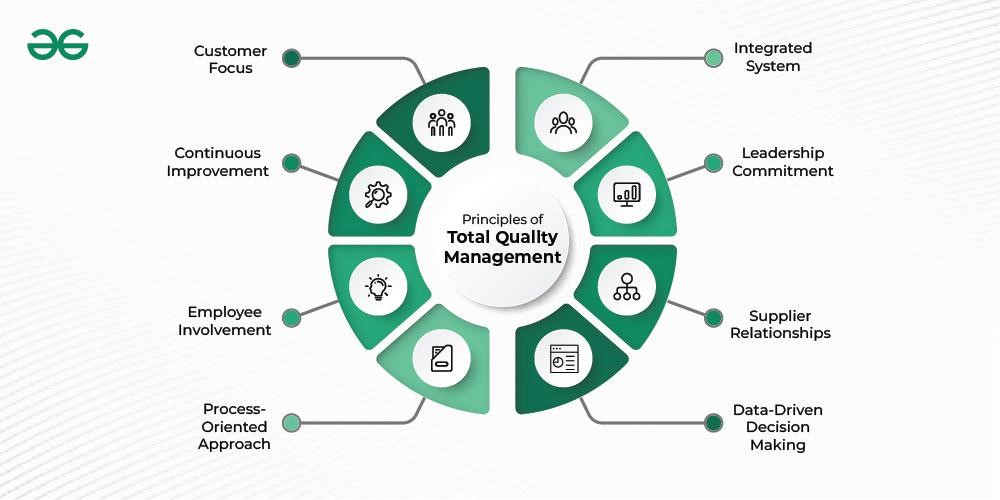

Total Quality Management (TQM)

Key components include process quality and fitness for use, ensuring that products not only meet customer needs but are also free from defects and inefficiencies.

Strategies for Plan Optimization in Manufacturing

Effective Plan Optimization in manufacturing requires a multifaceted approach that combines various strategies and techniques.

Demand-Driven Planning:

Aligning your production plans with actual customer demand, rather than relying on historical sales data or forecasts, can help you minimize inventory and improve responsiveness.

Capacity-Constrained Scheduling:

Identifying and addressing production bottlenecks by optimizing your scheduling and resource allocation can lead to significant improvements in throughput and efficiency.

Lean Manufacturing Principles:

Applying lean manufacturing principles, such as waste reduction, just-in-time production, and continuous improvement, can help you streamline your manufacturing processes and optimize your production plans.

Advanced Analytics and Simulation:

Leveraging data-driven analytics and simulation tools can provide valuable insights into your production operations, enabling you to identify optimization opportunities and test different scenarios.

Integrated Planning and Execution:

Aligning your planning and execution processes, and ensuring seamless communication and coordination between different departments, can help you respond more effectively to changes and disruptions.

Collaborative Optimization:

Engaging with suppliers, customers, and other stakeholders to optimize the entire supply chain, rather than just individual production processes, can lead to more holistic and effective plan optimization.

Collecting Real-Time Machine Data in Plan Optimization

Collecting real-time machine data in production optimization refers to the process of gathering and analyzing data from machines and equipment in real time to optimize production planning and operations. This data collection is done using various sensors, monitoring systems, and software tools that capture and transmit information about machine performance, productivity, and other relevant metrics.

Here is a detailed explanation of collecting real-time machine data in production optimization:

Data Collection:

- Sensors and monitoring systems are installed on machines and equipment to collect data on various parameters such as temperature, pressure, speed, vibration, energy consumption, and production output.

- These sensors are connected to a data acquisition system or an Industrial Internet of Things (IIoT) platform that collects stores, and processes the data in real time.

Real-Time Monitoring:

- The collected data is continuously monitored in real-time to track the performance of machines and equipment.

- Real-time monitoring allows operators and production managers to have immediate visibility into machine status, identify any deviations or anomalies, and take prompt action to address issues.

Data Analysis:

- The collected machine data is analyzed using advanced analytics techniques to gain insights into machine performance, efficiency, and potential areas for improvement.

- Data analysis can involve various techniques such as statistical analysis, predictive modeling, machine learning algorithms, and data visualization.

Production Optimization:

- The insights obtained from the analysis of real-time machine data are used to optimize production planning and operations.

- By understanding machine performance patterns, operators can identify opportunities for improving efficiency, reducing downtime, minimizing waste, and optimizing resource allocation.

- Real-time machine data can also be used for predictive maintenance, where potential equipment failures or maintenance needs are detected early, allowing for proactive maintenance actions to be taken.

Continuous Improvement:

- Collecting real-time machine data enables continuous improvement efforts by providing ongoing feedback on the effectiveness of production processes and optimization strategies.

- By monitoring key performance indicators (KPIs) derived from machine data, organizations can track their progress over time and make data-driven decisions to further optimize production operations.

Benefits of Collecting Real-Time Machine Data in Production Optimization:

- Improved Efficiency: Real-time machine data allows for quick identification of bottlenecks, inefficiencies, and performance issues, leading to targeted improvements in production processes.

- Reduced Downtime: Early detection of machine failures or maintenance needs through real-time monitoring helps minimize unplanned downtime and optimize maintenance schedules.

- Enhanced Decision-Making: Data-driven insights from real-time machine data enable better decision-making regarding production planning, resource allocation, and optimization strategies.

- Increased Productivity: Optimizing production operations based on real-time machine data leads to increased productivity, reduced cycle times, and improved overall equipment effectiveness (OEE).

Implementing Workflows & Notifications Based on Machine Sensors in Plan Optimization

Implementing workflows and notifications based on machine sensors in Plan Optimization involves utilizing real-time data from machine sensors to automate and optimize production workflows and processes. This approach enables organizations to proactively respond to changes in machine performance, production status, and other relevant parameters, leading to improved efficiency, reduced downtime, and enhanced decision-making. Here’s a detailed explanation of implementing workflows and notifications based on machine sensors in plan optimization:

Sensor-Based Data Collection:

- Machine sensors are installed to collect real-time data on various parameters such as temperature, pressure, speed, vibration, energy consumption, and production output.

- The collected sensor data is transmitted to a central system or an Industrial Internet of Things (IIoT) platform for processing and analysis.

Workflow Automation:

- Based on the real-time data from machine sensors, automated workflows can be implemented to streamline production processes and optimize resource utilization.

- Workflow automation involves setting up rules and triggers that automatically initiate specific actions or tasks based on predefined conditions or thresholds derived from sensor data.

Notification Systems:

- Notifications are configured to alert relevant personnel or systems when certain conditions or events occur based on the sensor data.

- Notifications can be sent via email, SMS, mobile apps, or integrated with existing communication and collaboration tools to ensure timely awareness of critical production-related information.

Plan Optimization:

- The real-time data from machine sensors is used to optimize production planning and scheduling by dynamically adjusting workflows and resource allocation based on current machine performance and production status.

- By integrating sensor data into the planning process, organizations can make more informed decisions regarding production priorities, job sequencing, and resource utilization.

Proactive Maintenance:

- Sensor data-driven workflows and notifications can be used to implement proactive maintenance strategies by triggering maintenance tasks or alerts based on predictive analytics or early detection of equipment issues.

- Proactive maintenance helps minimize downtime, reduce the risk of unexpected failures, and extend the lifespan of machinery and equipment.

Continuous Improvement:

- Implementing workflows and notifications based on machine sensors supports continuous improvement efforts by providing real-time feedback on production processes and enabling rapid adjustments to optimize operations.

- By analyzing historical sensor data and performance trends, organizations can identify areas for improvement and refine their workflows and notification systems to further enhance production efficiency.

Benefits of Implementing Workflows & Notifications Based on Machine Sensors in Plan Optimization:

- Enhanced Efficiency: Automated workflows and notifications based on sensor data enable streamlined production processes, reducing manual intervention and optimizing resource allocation.

- Reduced Downtime: Proactive notifications for maintenance or performance issues help minimize unplanned downtime and support predictive maintenance strategies.

- Improved Responsiveness: Real-time alerts and notifications enable quick response to changes in machine performance or production status, leading to more agile decision-making.

- Data-Driven Decision-Making: Sensor-based workflows provide actionable insights derived from real-time data, supporting informed decision-making for plan optimization.

In summary, implementing workflows and notifications based on machine sensors in Plan Optimization leverages real-time data to automate workflows, proactively manage production processes, optimize resource utilization, and support continuous improvement efforts. This data-driven approach enhances efficiency, reduces downtime, improves responsiveness, and enables informed decision-making for optimized production planning and operations.

Challenges and Solutions in Plan Optimization

While the benefits of Plan Optimization are well-documented, implementing and maintaining an effective plan optimization strategy can present a range of challenges. By anticipating and addressing these challenges proactively, you can develop a more robust and sustainable plan optimization strategy that delivers lasting benefits to your manufacturing operations:

- Data Availability and Quality: Ensuring that you have access to accurate, up-to-date data on your production operations is essential for effective plan optimization. Solutions may include implementing robust data collection and management systems, as well as integrating data from multiple sources.

- Organizational Resistance to Change: Plan optimization often requires significant changes to existing processes and workflows, which can meet resistance from employees. Addressing this challenge may involve effective change management strategies, such as clear communication, training, and incentivizing adoption.

- Complexity of Manufacturing Processes: The inherent complexity of many manufacturing processes can make it challenging to develop and implement effective optimization strategies. Solutions may involve the use of advanced analytics, simulation tools, and cross-functional collaboration to better understand and address these complexities.

- Supply Chain Disruptions: Unexpected disruptions in the supply chain, such as supplier delays or material shortages, can throw off even the most carefully optimized production plans. Strategies to address this may include building more flexibility and resilience into your supply chain, as well as developing contingency plans.

- Lack of Skilled Personnel: Effective plan optimization requires a combination of technical expertise, data analysis skills, and manufacturing domain knowledge. Addressing this challenge may involve investing in training and development, as well as recruiting and retaining talented individuals with the right skill sets.

Bottleneck Analysis in Plan Optimization

Bottleneck analysis in plan optimization involves identifying and addressing the key constraints or bottlenecks in a production process that limit overall throughput or efficiency. By analyzing the flow of work, resources, and information within a production system, organizations can pinpoint areas where capacity is constrained, leading to delays, inefficiencies, or reduced productivity. Here’s a detailed explanation of bottleneck analysis in plan optimization:

-

Identification of Bottlenecks:

- Bottlenecks are typically found in processes, machines, or resources that have the lowest capacity or highest utilization rate, causing them to slow down the overall production flow.

- Through data collection, observation, and performance metrics analysis, organizations can identify bottlenecks by comparing actual production rates with the maximum capacity of individual components in the production system.

-

Analysis of Impact:

- Bottlenecks can have a significant impact on production efficiency, lead times, and overall performance metrics such as cycle time, throughput, and resource utilization.

- By quantifying the impact of bottlenecks on key performance indicators, organizations can prioritize improvement efforts and allocate resources effectively to address the most critical constraints.

-

Optimization Strategies:

- Once bottlenecks are identified, organizations can implement various strategies to optimize production processes and mitigate the impact of constraints.

- Strategies may include reallocating resources, balancing workloads, improving process flows, upgrading equipment, implementing automation solutions, or redesigning workflows to streamline operations and increase throughput.

-

Continuous Monitoring and Improvement:

- Bottleneck analysis is an ongoing process that requires continuous production performance monitoring and regular evaluation of potential constraints.

- Organizations can proactively identify new bottlenecks, adjust strategies, and continuously improve plan optimization efforts by establishing a feedback loop for monitoring and analyzing production data.

Downtime Analysis in Plan Optimization

Downtime analysis in plan optimization focuses on identifying and reducing unplanned or planned downtime events that disrupt production processes and impact overall operational efficiency. By analyzing downtime causes, durations, and frequency, organizations can implement strategies to minimize downtime, improve equipment reliability, and enhance production uptime. Here’s a detailed explanation of downtime analysis in plan optimization:

-

Downtime Classification:

- Downtime events can be classified such as equipment failures, maintenance activities, changeovers, material shortages, operator errors, or external factors like power outages or supply chain disruptions.

- By categorizing downtime events, organizations can gain insights into the root causes and patterns of downtime occurrences within the production system.

-

Downtime Tracking and Analysis:

- Organizations track downtime events using real-time data from machine sensors, production logs, maintenance records, and other sources to analyze the frequency, duration, and impact of downtime on production performance.

- By conducting root cause analysis and Pareto analysis, organizations can identify the most common causes of downtime and prioritize improvement efforts based on their impact on production uptime.

-

Downtime Reduction Strategies:

- Based on the analysis of downtime data and root causes, organizations can implement strategies to reduce downtime and improve equipment reliability.

- Strategies may include preventive maintenance programs, predictive maintenance techniques, operator training, spare parts management, process optimization, automation solutions, or scheduling adjustments to minimize downtime events.

-

Performance Monitoring and Reporting:

- Continuous monitoring of downtime metrics and performance indicators enables organizations to track progress in reducing downtime and evaluate the effectiveness of implemented improvement initiatives.

- By generating reports and dashboards that provide visibility into downtime trends, organizations can make data-driven decisions to optimize production planning and mitigate the impact of unplanned disruptions.

-

Collaboration and Communication:

- Effective communication and collaboration among cross-functional teams are essential for addressing downtime issues and implementing sustainable solutions.

- By involving maintenance personnel, operators, engineers, planners, and other stakeholders in downtime analysis and improvement initiatives, organizations can leverage collective expertise to identify opportunities for enhancing plan optimization.

Benefits of Bottleneck Analysis and Downtime Analysis in Plan Optimization:

- Improved Efficiency: Identifying and addressing bottlenecks and downtime events leads to streamlined processes, increased throughput, and enhanced operational efficiency.

- Enhanced Reliability: By reducing unplanned downtime and improving equipment reliability, organizations can minimize disruptions and maintain consistent production output.

- Cost Savings: Optimizing production processes through bottleneck analysis and downtime reduction strategies helps reduce operational costs associated with inefficiencies, maintenance expenses, and lost production time.

- Data-Driven Decision-Making: Analyzing bottleneck and downtime data provides valuable insights for informed decision-making in plan optimization, enabling organizations to prioritize improvement efforts based on empirical evidence.

In summary, bottleneck analysis in plan optimization focuses on identifying constraints that limit production capacity, while downtime analysis aims to reduce disruptions that impact operational efficiency. By implementing strategies to address bottlenecks and minimize downtime events through data-driven analysis and continuous improvement efforts, organizations can enhance productivity, reliability, and cost-effectiveness in their production processes.

Tools and Technologies for Plan Optimization in Manufacturing

Leveraging the right tools and technologies is essential for successful Plan Optimization in manufacturing. By integrating these tools and technologies into your manufacturing operations, you can unlock the full potential of plan optimization, driving increased efficiency, cost savings, and overall operational performance. Some of the key tools and technologies that can support your efforts include:

Advanced Planning and Scheduling (APS) Software: APS software uses sophisticated algorithms and optimization techniques to generate detailed production schedules that take into account factors such as resource constraints, production priorities, and delivery deadlines.

Manufacturing Execution Systems (MES): MES solutions provide real-time visibility into your production processes, allowing you to monitor performance, identify bottlenecks, and make more informed planning decisions.

Simulation and Modeling Tools: Specialized simulation and modeling software can help you analyze the impact of different planning scenarios, test optimization strategies, and validate the feasibility of your production plans.

Predictive Analytics and Machine Learning: By leveraging predictive analytics and machine learning algorithms, you can develop more accurate demand forecasts, identify potential supply chain disruptions, and optimize your production plans accordingly.

Collaborative Planning Platforms: Cloud-based collaborative planning platforms enable you to share information, coordinate with suppliers and customers, and jointly optimize your production plans across the entire supply chain.

Best Practices for Implementing Plan Optimization in Manufacturing

To ensure the successful implementation of Plan Optimization in your manufacturing operations, consider the following best practices:

Establish Clear Objectives and Key Performance Indicators (KPIs): Define specific, measurable goals for your Plan Optimization efforts, and identify the KPIs that will be used to track and measure success.

Ensure Cross-Functional Collaboration: Involve stakeholders from across your organization, including production, supply chain, finance, and IT, to ensure that your plan optimization efforts are aligned with the broader business objectives.

Adopt a Continuous Improvement Mindset: Treat Plan Optimization as an ongoing process, not a one-time project. Continuously monitor and analyze your performance, and be willing to adjust your strategies and tactics as needed.

Leverage Data-Driven Insights: Utilize advanced analytics, simulation tools, and other data-driven technologies to gain a deeper understanding of your manufacturing processes and identify opportunities for optimization.

Foster a Culture of Experimentation: Encourage a culture of experimentation and innovation, where employees are empowered to test and implement new ideas for improving production plans and processes.

Invest in Employee Training and Development: Ensure that your employees have the necessary skills and knowledge to effectively implement and maintain your plan optimization strategies.

Integrate Plan Optimization with Other Operational Initiatives: Align your Plan Optimization efforts with other operational initiatives, such as lean manufacturing, Six Sigma, and Industry 4.0, to create a more holistic and effective approach to improving manufacturing performance.

By following these best practices, you can increase the chances of successfully implementing and sustaining your plan optimization efforts, ultimately driving long-term improvements in your manufacturing operations.

Future Trends in Plan Optimization

As the manufacturing industry continues to evolve, we can expect to see several exciting trends and advancements in the field of plan optimization. Some of the key trends to watch out for include:

Increased Adoption of Artificial Intelligence and Machine Learning:

AI in manufacturing and machine learning algorithms will play an increasingly important role in Plan Optimization, enabling more accurate demand forecasting, predictive maintenance, and real-time decision-making.

Greater Integration of IoT and Edge Computing:

The integration of IoT devices and edge computing technologies will provide manufacturers with unprecedented visibility into their production processes, allowing for more granular and responsive plan optimization.

Emphasis on Sustainability and Environmental Responsibility:

Plan Optimization strategies will need to consider the environmental impact of manufacturing operations, driving the development of more sustainable production practices and the optimization of energy and resource usage.

Collaborative Planning Across the Supply Chain:

Manufacturers will increasingly collaborate with suppliers, customers, and other stakeholders to optimize production plans and supply chain operations, leveraging cloud-based platforms and advanced data-sharing technologies.

Personalization and Mass Customization:

As consumer demand for personalized products continues to grow, Plan Optimization will need to adapt to support more flexible and agile production processes that can accommodate customization and rapid changeovers.

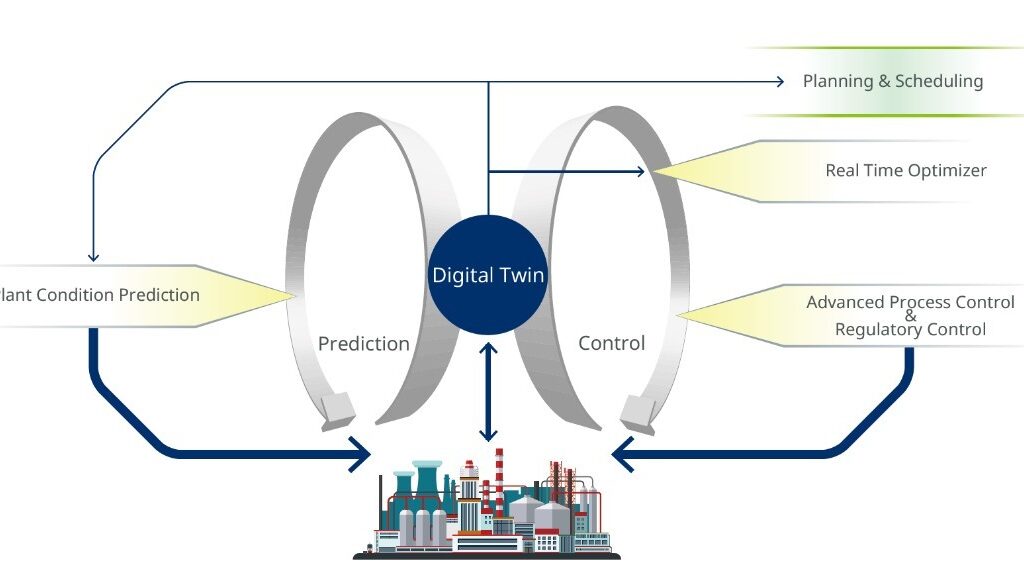

Increased Adoption of Digital Twins:

The use of digital twins, or virtual representations of physical manufacturing systems, will enable more accurate simulation and optimization of production plans, leading to improved decision-making and operational performance.

By staying attuned to these emerging trends and proactively adapting your Plan Optimization strategies, you can position your manufacturing business for long-term success in the years to come.

Conclusion

Throughout this exploration of advanced Plan Optimization techniques in manufacturing, we have delved into the key strategies, tools, and approaches that underscore the importance of efficient and effective production processes. From the integration of lean manufacturing principles and the implementation of Six Sigma to the adoption of cutting-edge tools like Data Analytics and Simulation Software, these methodologies collectively enhance productivity, reduce costs, and streamline operations.

Looking forward, the manufacturing industry stands on the brink of a technological revolution, with AI and machine learning, digital twins, and a heightened focus on sustainability poised to redefine traditional practices. These future trends not only promise greater operational efficiencies but also hold the potential for a more sustainable, responsive manufacturing ecosystem. As manufacturers continue to navigate the challenges and opportunities presented by an increasingly competitive global market, the strategic application of these advanced optimization techniques and technologies will be crucial in achieving lasting success and innovation in manufacturing processes.