Overall Equipment Efficiency (OEE) stands as a gauge employed to evaluate the efficiency and efficacy of manufacturing procedures or any particular piece of machinery. It furnishes perspectives into the degree of equipment utilization and the degree of its efficiency when generating products or dispensing services.

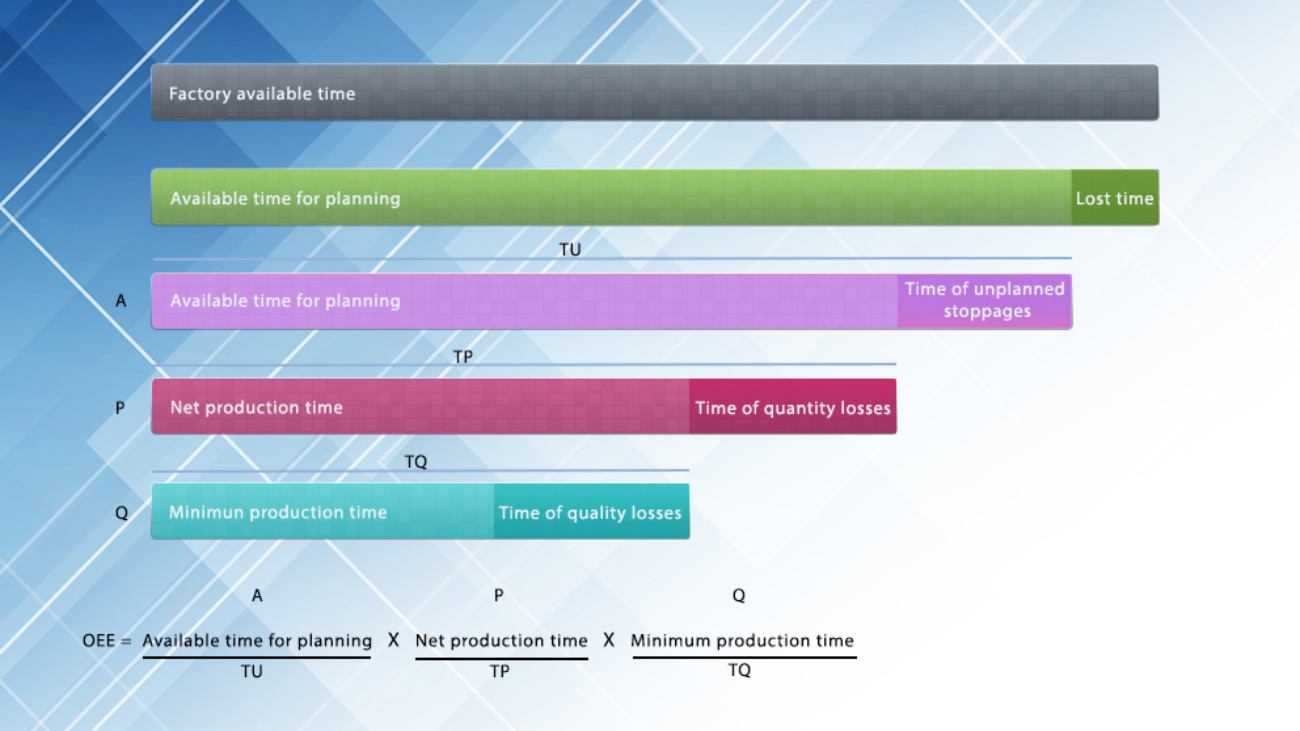

OEE = Availability x Performance x Quality

Availability: The accessibility rating quantifies the real manufacturing duration in contrast to the scheduled production duration. It factors in elements like machinery.

Performance: The efficiency rating evaluates the equipment’s operational prowess in relation to its utmost capability. It takes into account variables such as equipment velocity, brief interruptions, and idle periods.”

Quality: This assesses the pace of producing products with a ‘good count,’ free from flaws or the need for rework. It considers variables like waste, discards, and reworking.

The outcome is presented as a percentage, signifying the all-encompassing efficiency of the machinery or procedure. A heightened OEE percentage denotes superior performance and efficacy, while a diminished percentage hints at potential enhancements. OEE serves as a prevalent performance measure in manufacturing sectors, helping to pinpoint optimization opportunities, monitor progressive advancements, and gauge disparities between various equipment or production sections.

Enhanced productivity:

Enhancing OEE leads to a direct enhancement in productivity. Through the reduction of unproductive periods, fine-tuning equipment efficiency, and the mitigation of quality concerns, enterprises can attain elevated production rates and yields without necessitating supplementary resources or capital investments.

Enhanced effectiveness:

Elevating OEE aids in the detection and resolution of ineffectual aspects within the production sequence. Through the fine-tuning of equipment application, the curtailing of unproductive intervals, and the rationalization of manufacturing activities, enterprises can optimize their resource utilization, resulting in an overall boost in effectiveness.”

Expense curtailment: Augmented OEE frequently results in lowered expenditures, fortifying the financial performance. By curbing equipment downtime, establishments can evade expensive production interruptions. Elevating quality and diminishing imperfections aids in the reduction of waste, reworking, and material squandering, ultimately yielding economic advantages.”

Heightened Quality

Initiatives to enhance OEE generally concentrate on diminishing imperfections, enhancing process reliability, and ensuring a uniform product standard. By recognizing and rectifying quality dilemmas, establishments can provide commodities that match or outperform customer anticipations, resulting in heightened customer contentment and allegiance.

Enhanced capability: Through the fine-tuning of equipment application and the alleviation of constraining factors, augmenting OEE has the potential to augment the total capability of the production system. This empowers establishments to manage larger quantities, cater to escalating customer requisites, and potentially broaden their enterprise without substantial capital outlays.

Equipment reliability and durability: Oftentimes, elevating OEE includes anticipatory upkeep and vigilance regarding machinery. By enacting preventive maintenance schemes and swiftly resolving concerns, organizations can amplify equipment dependability, prolong the operational life of their equipment, and reduce the odds of unanticipated malfunctions.”